SANITARY PRESSURE REGULATORS

P130G

The ADCA P130G series direct-acting, spring-loaded diaphragm sensing, balanced plug, pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for anything with high sanitary requirements including the high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

11/2 DN 32 and DN 40

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 4,2 to 6,3

P130H

The ADCA P130H series direct-acting, spring-loaded diaphragm sensing, balanced plug, pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for the high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

1 DN 25

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 3,2 to 4,2

P130J

The ADCA P130 series direct-acting, spring-loaded diaphragm sensing, pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for sanitary requirements in high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

1/2 to 1 DN 08 to DN 25

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 1,7 to 2,4

P130K

The ADCA P130 series direct-acting, spring-loaded diaphragm sensing, pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for the high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

1/2 to 3/4 DN 08 to DN 20

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 0,7 to 1,3

P130L

The ADCA P130L low flow series direct-acting, springloaded diaphragm sensing, pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for the high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

1/2 to 3/4 DN 08 to DN 20

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 0,06 to 0,25

P147

The ADCA P147 series sanitary pilot operated pressure reducing valves are designed for use with clean air, nitrogen, carbon dioxide, oxygen, argon and other gases or liquids compatible with the construction materials and valve design. This valve is specifically designed for the high purity gas systems found in the pharmaceutical, cosmetic, fine chemical and food & beverage processes.

MATERIALS

Stainless steel

SIZES

21/2 to 3 DN 65 to DN 80

CONNECTIONS

ASME BPE and DIN clamp ferrules

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

Kvs 16,8 to 307

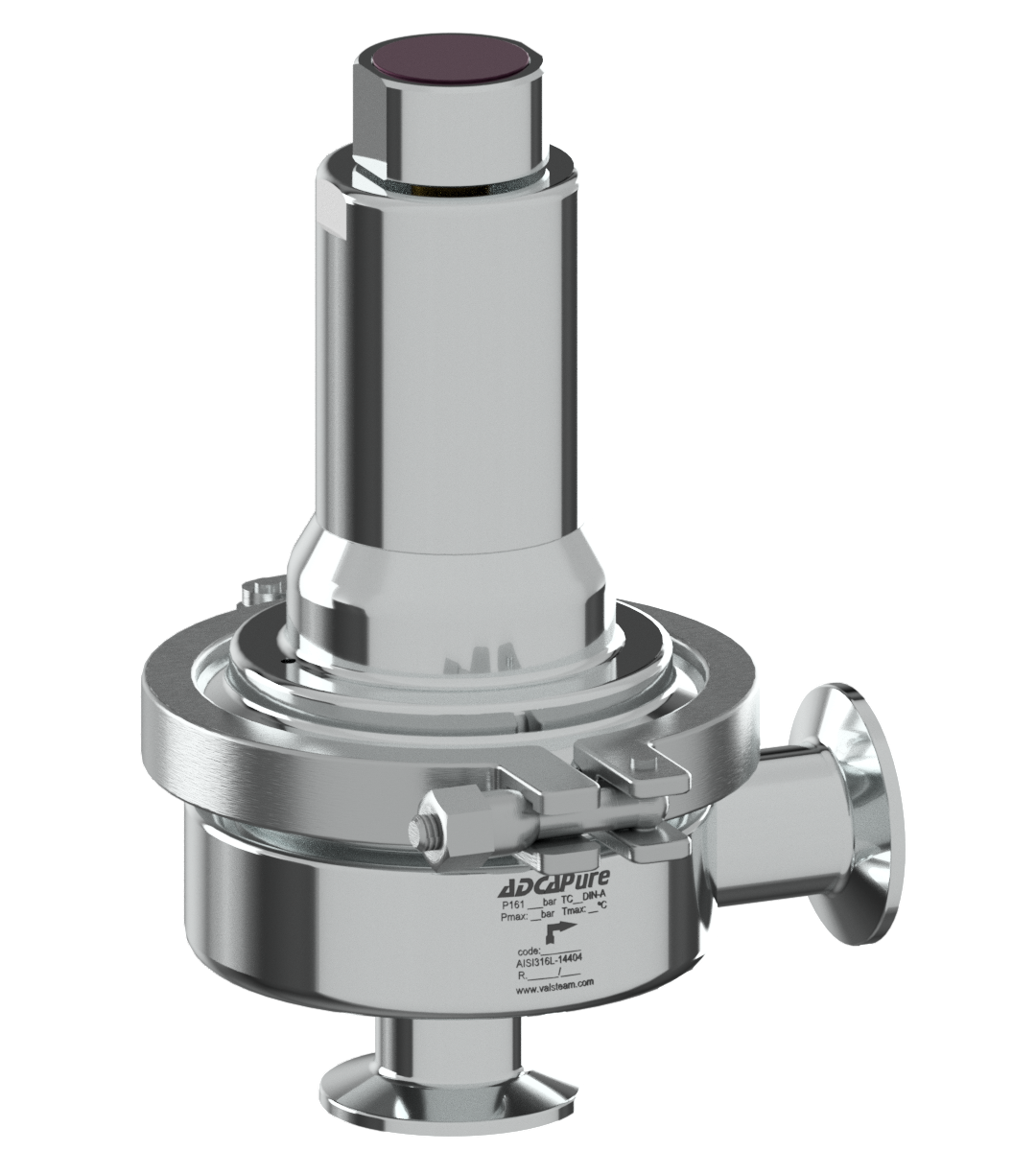

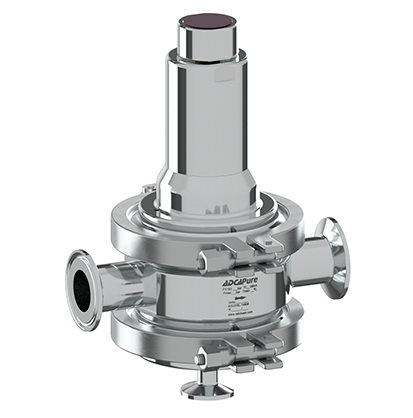

P161

The ADCAPure P161 is a series of angle design direct acting diaphragm sensing sanitary pressure reducing valves. These regulators, available with spring or dome-loading, are designed for use with clean steam, compressed air, water and other gases or liquids compatible with the construction materials and valve design.

MATERIALS

Stainless steel

SIZES

1/2 to 2; DN 15 to 50

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

8 bar

MAX. DESIGN TEMPERATURE

180 ēC

REGULATING RANGE

0,3 to 5 bar

FLOW RATE COEFFICIENTS

Kvs 1.3 to 13.0

P160G

The ADCA P160 series direct-acting, spring-loaded, diaphragm sensing sanitary pressure reducing valves are designed for use with clean steam, compressed air, water and other gases or liquids compatible with the construction materials.

MATERIALS

Stainless steel body

SIZES

21/2 and 3

CONNECTIONS

ASME BPE Clamp ferrules or others on request

MAX. UPSTREAM PRESSURE

16 bar

MAX. DESIGN TEMPERATURE

150 ēC*

REGULATING RANGE

0,2 to 8 bar

FLOW RATE COEFFICIENTS

16,8 to 307 Kvs (m3/h)

P163

The ADCAPure P163 is a series of inline direct acting, diaphragm sensing pressure reducing valves. These regulators, available with spring or dome-loading, are designed for use with clean steam, compressed air, water and other gases or liquids compatible with the construction materials and valve design.

MATERIALS

Stainless steel

SIZES

1/2 to 2 DN 15 to 50

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules

or tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

8 bar

MAX. DESIGN TEMPERATURE

180 ēC

REGULATING RANGE

0,8 to 5 bar

FLOW RATE COEFFICIENTS

Kvs 1,3 to 13

P173

The ADCA P173 series direct-acting, spring-loaded diaphragm sensing, sanitary pressure reducing valves are designed for use with clean steam, compressed air, water and other gases or liquids compatible with the construction materials.

MATERIALS

Stainless Steel

SIZES

11/2 to 2 DN 32 to DN 50

CONNECTIONS

ASME BPE, DIN and ISO clamp ferrules or

tube weld (ETO) ends

MAX. UPSTREAM PRESSURE

8 bar

MAX. DESIGN TEMPERATURE

150 ēC

REGULATING RANGE

0,8 to 5 bar

FLOW RATE COEFFICIENTS

Kvs 5,5 or 8,5